Around 300 900 times per minute.

Nibbling process sheet metal.

Oblong and rectangular punches are common because they minimize waste and allow for greater distances between strokes as compared to a.

The kerf is around 2 7mm and will cut without deformation.

Punching nibbling is suitable for thin sheets up to 3 mm and makes it possible to deform the material eyes small folds stamped parts threading.

10 coupon applied at checkout save 10 with coupon.

Punching or die cutting is a sheet metal forming method which is always used if metal sheet or plate parts have to be made with recurring recesses cutouts louvres or beads.

The sheet moves under the press containing the tool.

10 coupon applied at checkout save 10 with coupon.

Double headed sheet metal nibbler 360 degree illuminate ultimate metal cutter for straight circle and round cutting burr free edge extra punch and die 1 cutting hole accessory and 1 step drill bit.

If all the elements to be formed are the same punching is superior to other cutting methods such as laser cutting in terms of production speed.

The video is a part.

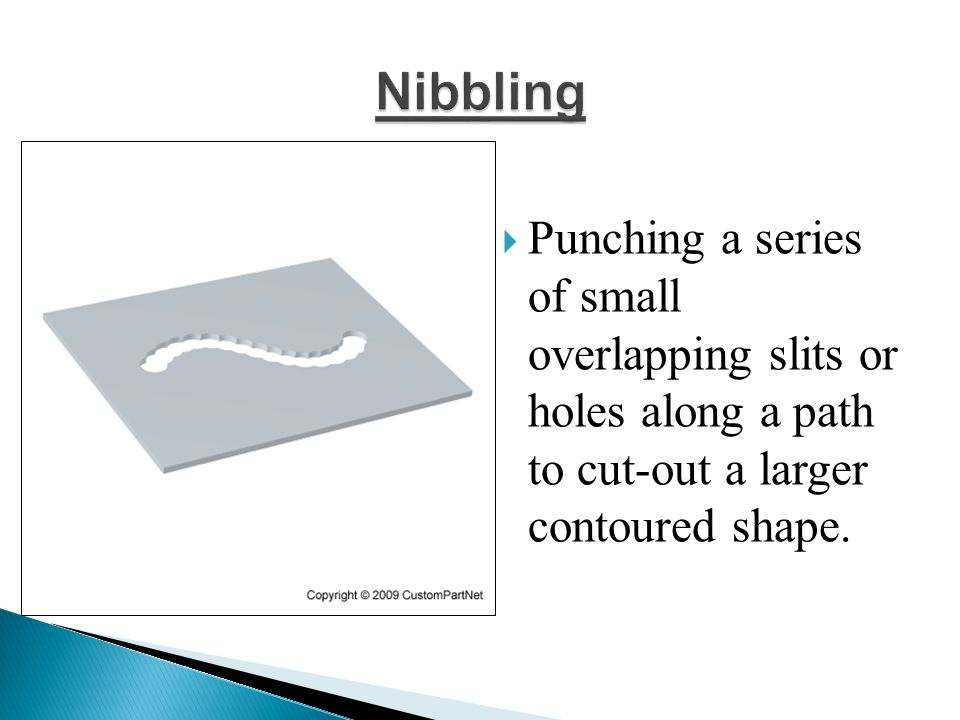

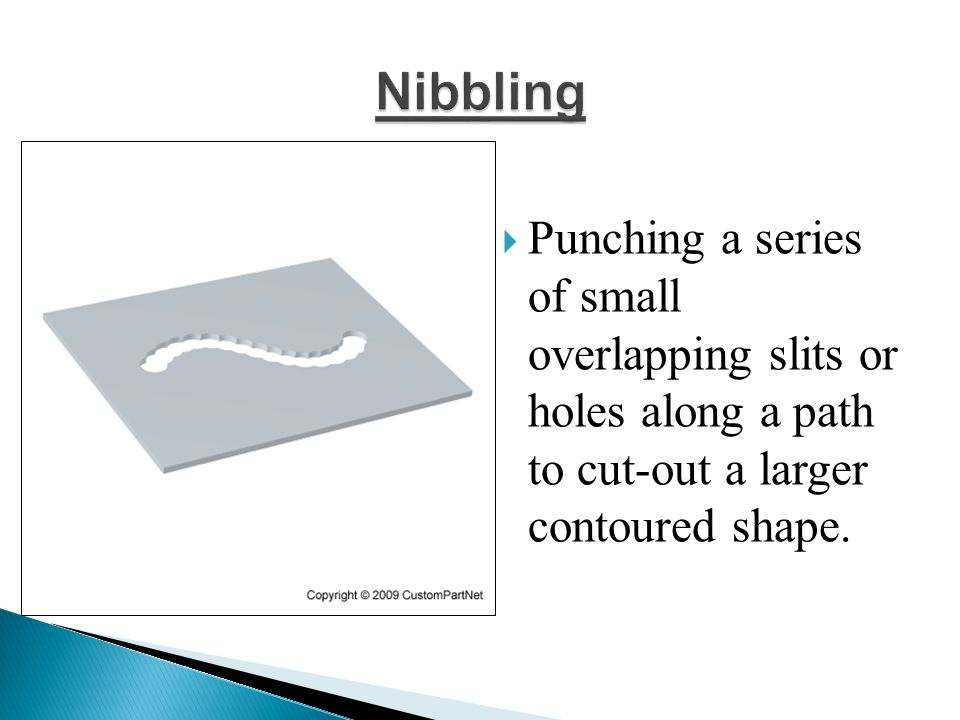

Nibbling is a method to punch overlapping holes in sheet metal.

If a larger piece of sheet metal is to be removed it is also possible to nibble along its contours to do the process more efficiently.

This video gives a clear picture of how the nibbling process is similar to the punching process and how it is used to cut complex shapes.

Punches are available in various shape and sizes.

4 3 out of 5 stars 223.

This happens at the top and bottom surfaces since the bottom cutting die is pushing up with the same force that the punch is pushing down.

Nibbling is when a large number of holes are punched in sheet metal.

As the holes overlap it is possible to remove material without the need for special tools.

This allows for complex shapes to be formed in sheet metal up to 6 mm 0 25 in thick using simple tools.

The nibbling process cuts a contour by producing a series of overlapping slits or notches.

They work on iron copper or aluminum sheets that are up to 1 2 mm thick.

This high speed results from the use of punching tools which we have in stock in various shapes and sizes.

They barely weigh a pound and allow for really tight radiuses to be cut.

In manufacturing practice the plastic deformation occurring at the surfaces of the sheet metal at this stage in the cutting operation is referred to as rollover.

This process combines forward movement of the sheet that is being cut with vertical movement of the cutting tool.

Punching nibbling is a process that removes the material by making holes classic punching or by cutting inner or outer profiles by means of multiple punching strokes nibbling.

Rapid make paradise brand sheet metal nibbling machine available in three models pn 3 pn 5 pn 8.

That is essentially a small punch and die that reciprocates quickly.