A lot goes into installing a stove once you have chosen your favourite style you ve then got to make sure you have all the parts in their right places.

Multi fuel chimney liner regulations.

If you order a flexible liner kit or full twinwall flue sysytem from us it will come with the suitable adaptor to connect to the 5 or 6 enamel pipe.

Shop all chimney liners log burner hearth regulations.

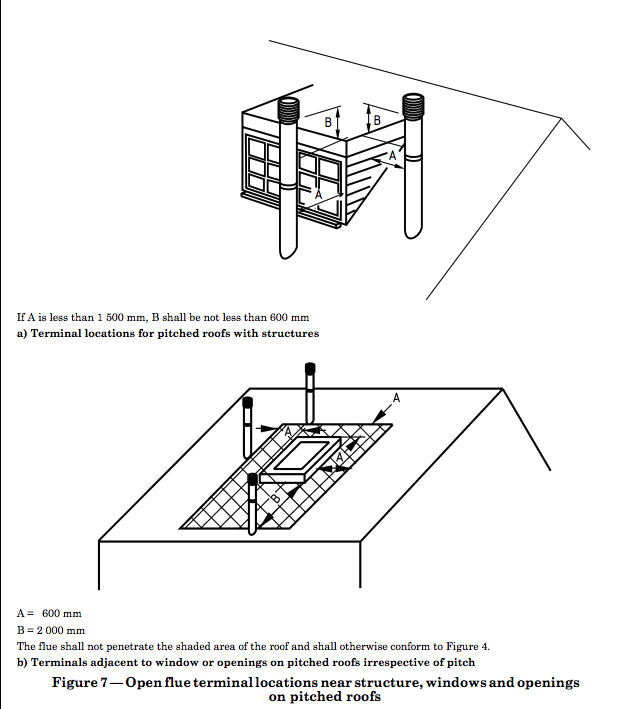

The minimum chimney height recommended for minimum performance of wood burning and multi fuel appliances is 4 5 m from the top of the appliance to the top of the chimney.

You can choose from an outstanding selection of stoves as well as flue liner and supplies outdoor ovens and stove accessories all with free delivery.

Our competitors tend to use 0 10mm thick stainless steel which is equal to 20 less steel per mtr so buyer beware it may seem cheap but its cheap for a reason.

Gas flue block systems.

Why line a chimney.

New chimneys may require relining to suit the fuel type being used a gas flue liner may not be suitable for other fuels.

That applies to most solid fuel appliances.

Something of the back bone of your stove they are responsible for making sure you can burn your fuel effectively and safely.

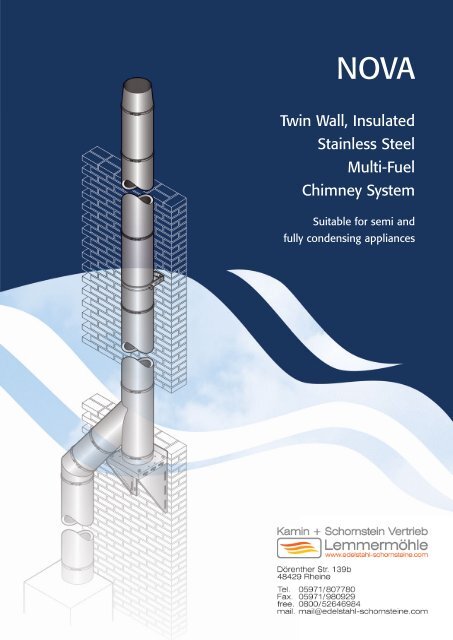

Ceramic chimney systems and liners are suitable for wood multi fuel oil and gas and condensing applications.

You will find the following additional information useful and helpfull.

Do make sure the liner is matched to your new fire or stove and suitable for the fuel you will burn.

Ceramic chimney systems are certified to bs en13063 1 2005.

From that point you will then usually have to change to a minimum 6 150mm flexible chimney liner or rigid insulated flue system.

For over 10 years direct stoves has been supplying homeowners like you with range cookers and multi fuel and wood burning stoves.

Chimneys are lined for a number of safety reasons.

To make matters easier just do not join two or more pieces of liner together.

5 125mm 316 316 multi fuel chimney liner.

Flue liners for wood burners are one of the most important pieces of the puzzle.

Chimney systems that predate 1965 will often require a modern lining solution for the following reasons.

Usually constructed of sectional flue liners and components made from clay ceramic and concrete a new chimney can be formed by surrounding the liners with at least 100mm of brick filling around the liners with vermiculite or insulating concrete.

The inner ceramic liner is insulated with rock wool and contained in a preformed concrete block.

If the lining is found to be porous and leaky you will need to either have the chimney re lined fit a new prefabricated liner or use a manufactured flexible metal liner.

Manufactured from 0 12mm thick stainless steel on both inner and outer skin.